Unmanned Helicopter Blade

CUSTOMER REQUEST

Existing CTT customer was facing quite a challenge. Customer requirements for UAV equipment have pushed the takeoff weight of the helicopter to a point where the engine was not able to provide smooth performance. Increasing the engine size would greatly impact the cost of the product, so an alternate solution was preferred.

Customer contacted CTT asking for a new rotor blade to be designed that could generate more lift than the existing one, hoping that an incremental increase in lift would avoid the need for a larger engine.

CHALLENGE

This project required research and development, engineering, manufacturing and testing to be performed with not a lot of time at hand. All of this had to be done knowing that a failure to generate enough incremental lift would result in financial loses to our long standing customer.

SOLUTION

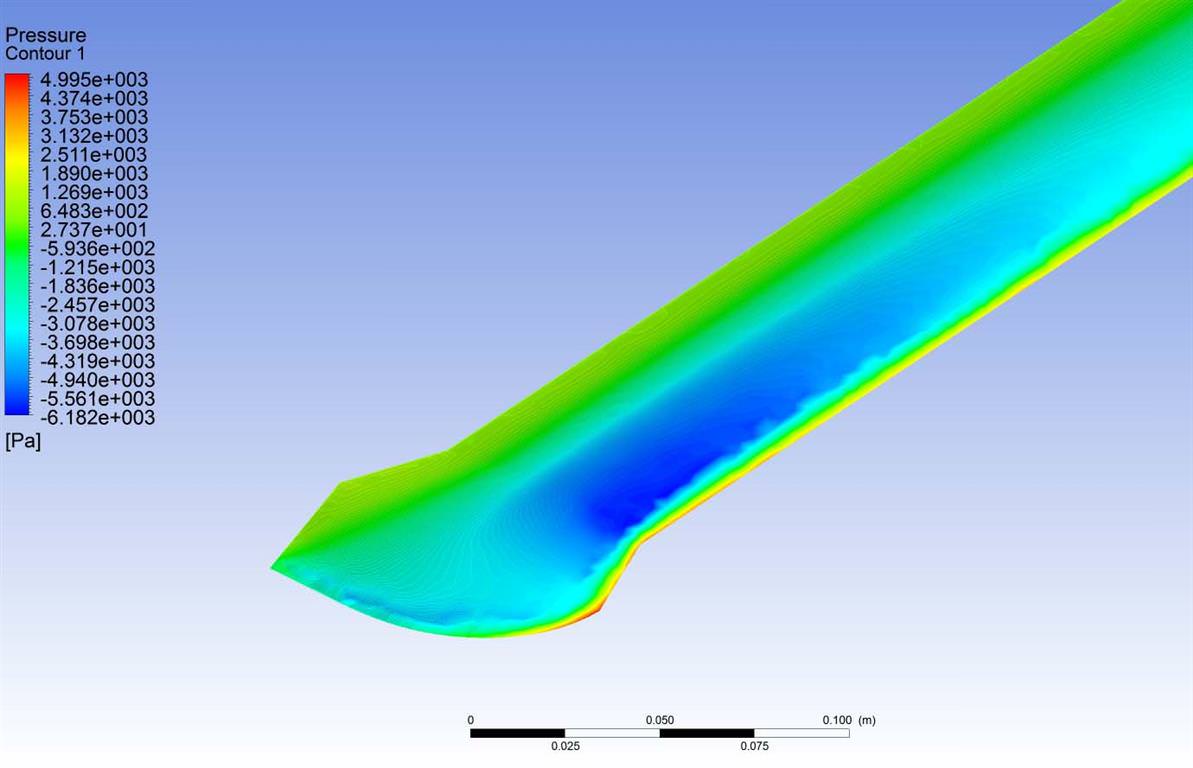

Initial aerodynamic analysis showed that the incremental lift requirement was achievable. The main question that needed to be answered is whether the cost of development and manufacturing would have the same net financial effect as increasing the size of the engine.

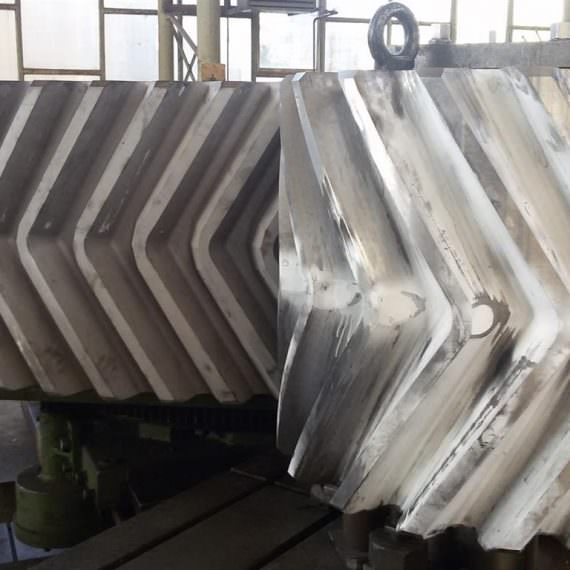

CTT engineers engineered a new blade and CFD analysis showed that the expected performance is in line with the requirements. Design drawings were released to the shop floor and special tooling was made for prototype production. Lost of attention needed to be placed on the design of the materials to ensure that the blade could withstand the lift and the centrifugal forces that are exerted on it.

To verify the final design, CTT had to perform structural testing, where series of weights were attached to the blade in line with the expected maximum loads. As expected, the product passed with flying colors.

CTT was very happy to deliver the final design and testing report to the customer that resolved their pressing problem.